We present our polypropylene new grades under development for printed electronics at the PIAE

We have participated in the PIAE latest edition, the plastic expert's world's largest congress related to the automotive industry. During the meeting, held in Germany, we showcased our new polypropylene (PP) grades for printed electronics and injection materials, together with our partner TactoTek.

Our colleague Andreas Benndorf, Advanced Automotive Solutions Senior Engineer, together with Antti Keränen TactoTek Chief Technology Officer, has participated in the PIAE to show two new developments of polypropylene which allow the creation of a new type of structure for smart surfaces.

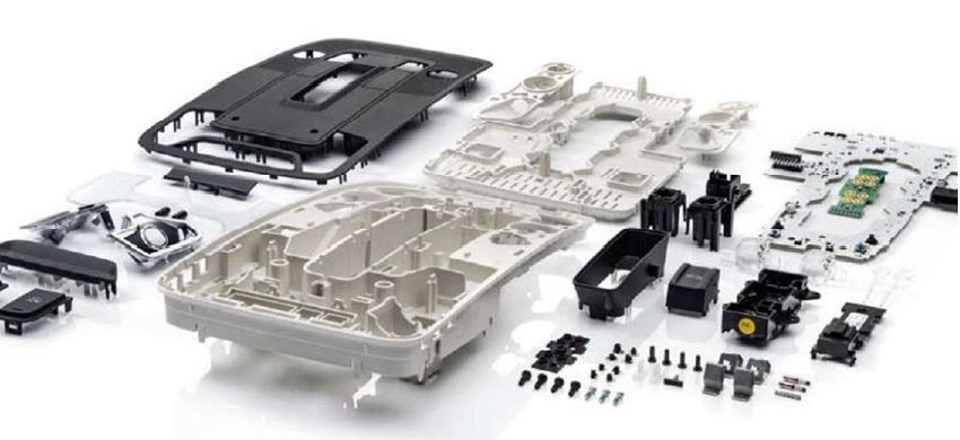

Polypropylene is one of the most used materials in the automotive industry. However, there are no solutions on the market that incorporate printed electronics based on this material. This novelty represents a revolution for the sector, as until a few years ago, any electrical circuit consisted of different components. Today, thanks to printed electronics and injection molding processes, it can be manufactured much more compact and functional pieces with great design freedom.

During their speech, they valued the efforts made to develop new materials that can be used as films for electronic circuit printing, as well as injection materials with applications for the automotive sector.

At Repsol, we are developing new materials that can be used as films to manufacture parts with IMSE® technology (structural electronics by molding or in-mold structure electronics) that Tactotek has patented. This innovative process integrates standard electronic and printed electronic components such as LEDs into injection molded three-dimensional parts.

Currently, we have a double challenge, on the one hand, to modify polypropylene resins to improve our grades optical properties for injection components manufacturing and, on the other hand, to design new grades that allow obtaining films that allow to be used in printed electronic circuits for pieces with new properties.

In this sense, during his speech, Andreas described: "Weight reduction represents a great sustainability challenge for the automotive sector, since it contributes to reducing CO2 emissions, in addition to polypropylene it is a recyclable material, in line with our strategy sustainability and circular economy.

At Repsol, we work to recover materials used in cars that have reached the end of their useful life, demonstrating our commitment to sustainability and the circular economy.