Press

Repsol posts adjusted net income of €2.568 billion

Repsol reported a net income of €1.899 billion in 2025, an increase of 8% compared to the previous year. Adjusted net income stood at €2.568 billion, 15% lower than in 2024.

Press Release

19 February 2026

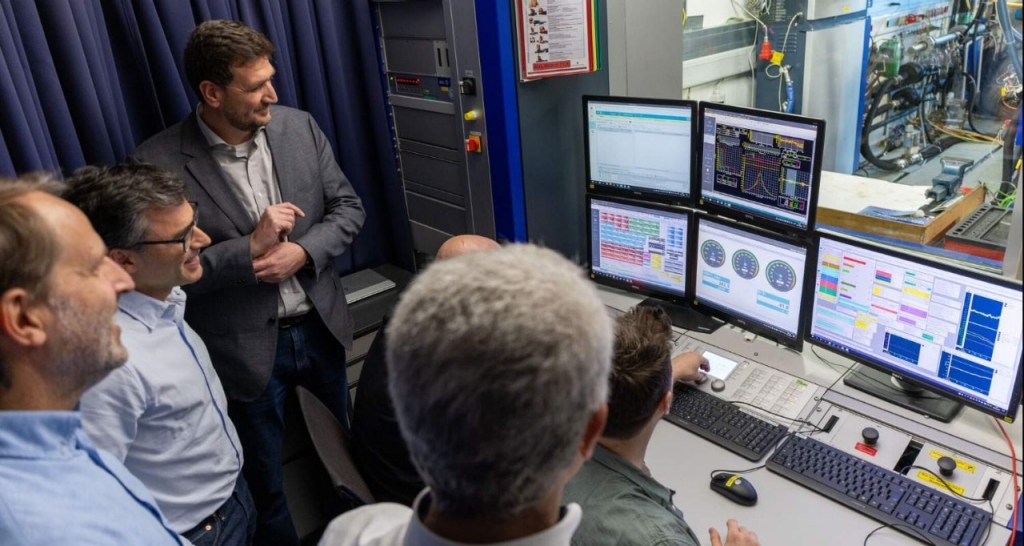

Horse Powertrain and Repsol jointly develop a highly efficient hybrid powertrain running on 100% renewable gasoline

Horse Powertrain, via its Horse Technologies division, and Repsol have unveiled a next-generation hybrid powertrain that achieves ultra-high efficiency and low fuel consumption.

Press Release

16 February 2026

Repsol installs its second 100-MW electrolyzer at Petronor

The new plant for producing renewable hydrogen will require an investment of €292 million.

Press Release

26 January 2026

Repsol surpasses 1,500 service stations in Spain and Portugal offering 100% renewable Nexa Diesel

The multi-energy company consolidates its leadership in renewable fuels with 1,500 stations offering 100% renewable Nexa Diesel and meets the target set in the updated 2024-2027 strategic plan.

Press Release

29 December 2025

Repsol receives a Platts Award for its deployment of 100% renewable fuels in Spain and Portugal

Repsol has received the award in the Excellence in Energy - Downstream category for the roll-out of NEXA fuels of 100% renewable origin in 1,500 service stations in its network in Spain and Portugal, one of the largest European networks for the commercialization of renewable fuels.

Press Release

12 December 2025

Repsol advances its renewable energy strategy in the US with a new deal with Stonepeak

Stonepeak will acquire a 43.8% stake in the Outpost solar project (629 MW) from Repsol for $252.5 million (€220 million).

Press Release

11 December 2025

Repsol and HitecVision to merge their joint venture with TotalEnergies’ UK upstream business, becoming the leading oil &gas operator in the UK North Sea

The addition of TotalEnergies UK’s operated high quality producing assets will strengthen NEO NEXT’s balance sheet, reinforce its operational capabilities and support its development activities, ensuring a long-term resilient future for its oil and gas business in the UK.

Press Release

08 December 2025

Press release notification

Would you like to receive our press releases?

Subscribe and receive them directly in your box.

Confirm your subscription

Please check your inbox and validate your registration by clicking on the link you have received.

Don't forget to check your spam folder first.

The registration could not be completed successfully

Please try again, if the error persists try again later.

Multimedia gallery

images image

Contact us

Contact us

Have any questions? Get in touch with us and our agents will help you.

Updated as of February 2026