Other scientific projects

To advance in the reduction of CO2 emissions in air transport, we coordinate the "Madrid Vuela Sostenible" project in collaboration with IMDEA Energía, ARIEMA, and EVOENZYME.

With the support of the Community of Madrid and the European Union in this project, we meet the objective of promoting the generation and dissemination of knowledge on technologies for the reduction of CO2 and the circular economy, promoting the transformation of renewable fuel waste for aviation.

This project aims to design and build a smart charging hub for electric vehicles, located at a service station in Manzanares (Ciudad Real).

The new space will offer an advanced and flexible infrastructure that will allow the response to the different charging needs of different types of users, integrating in turn into the services of the station itself. This way, customers will be able to have a service adapted to their demands, combining the charging of their vehicles with other common uses at a service station.

It is developed within the framework of the MOVES Program for Unique Projects II, managed by the Institute for Energy Diversification and Savings (IDAE) and has the financial support of the European Union – NextGenerationEU, through the Spanish government's Recovery, Transformation, and Resilience Plan (PRTR).

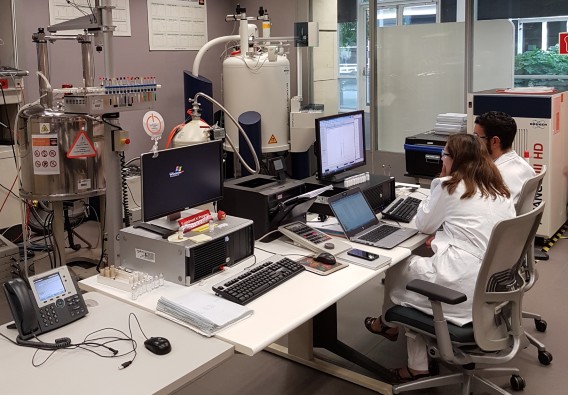

EfiSOEC is a development project focused on studying and designing an integrated system for highly efficient and durable renewable hydrogen production. The technology under development is based on high-temperature electrolysis cells known as SOCEs (solid oxide electrolysis cells), which offer increased efficiency over current technologies.

EfiSOEC is backed by a business consortium and a network of research organizations from across Spain, namely Repsol, Técnicas Reunidas, Tubacex, EPowerLabs, and Zigor, all of whom are working together to develop last-generation electrolyzers that can help further the integration of renewable energies.

Repsol has received funding from the Ministry for Ecological Transition and Demographic Challenge and the MOVES Program for Unique Projects II, part of the Spanish government's Recovery, Transformation, and Resilience Plan (PRTR) and the EU's Recovery and Resilience Facility (MRR), for the project "Smart Charging: smart cloud-based charging platform for B2B electric vehicle fleets (Plataforma Cloud de recarga inteligente (Smart Charging) para flota de vehículo eléctricos B2B)." The project aims to develop a cloud-based smart charging platform for B2B electric vehicle fleets that will rely on business intelligence techniques to facilitate improved management of electric vehicle recharging infrastructures, thereby incentivizing and promoting the use of electric vehicles.

The project has been accepted by the incentivization program for unique electric mobility projects and has received European Union/NextGenerationEU funding.

CirQlar will overcome some barriers in low-temperature heat recovery technology, such as the optimisation of the thermodynamic cycle, the reliability of the machines working in severe conditions, and its integration into an energy network. This is driven by the fact that heat pumps are the best low temperature heat recovery route in terms of decarbonization, due to the inherent electrification process and the amount of energy recovered.

CirQlar will reinforce the EU industry value chain of waste heat recovery and heat pumps, providing a cost-competitive technology to the market. It will deliver more sustainable processes with lower emissions, which will respond to today's environmental challenges, while also reducing consumption and dependence on natural gas throughout the EU.

Quantum computing research applied to strategic industries of the Spanish economy, such as Energy, Finance, Space, Defense, and Logistics, is already underway. This is based on scientific and technological knowledge of quantum computing algorithms as a way to implement this technology in the industry in the medium term. In order to do so, a number of important cases regarding the Spanish economy will be previously studied, and it'll be determined if quantum computing would lead to improvements. These cases involve observation of the Earth, the fight against climate change, the environment, traceability of information throughout the entire supply chain, among others.

The ECLIPSE Project, which is promoted by the Spanish Center for the Development of Industrial Technology (CDTI), is aimed at the recycling of plastic. It will consist in researching new technological paths that facilitate the recycling and recovery of complex polymeric waste (plastics) and that entail significant progress compared to the current process (mechanical recycling), which currently has its limitations. Its purpose is to achieve a comprehensive, sustainable, and circular recycling and recovery system for complex plastic waste that's versatile, tested in the automotive industry, and transferable to all strategic industrial sectors.

We have joined the European Economic Area-Grants projects, funded by the European Union to improve the environment and fight against climate change. Learn more about our projects, which are focused on creating advanced materials that save energy and are environmentally friendly. From biofuels made from waste to rubber for tires. See all the projects:

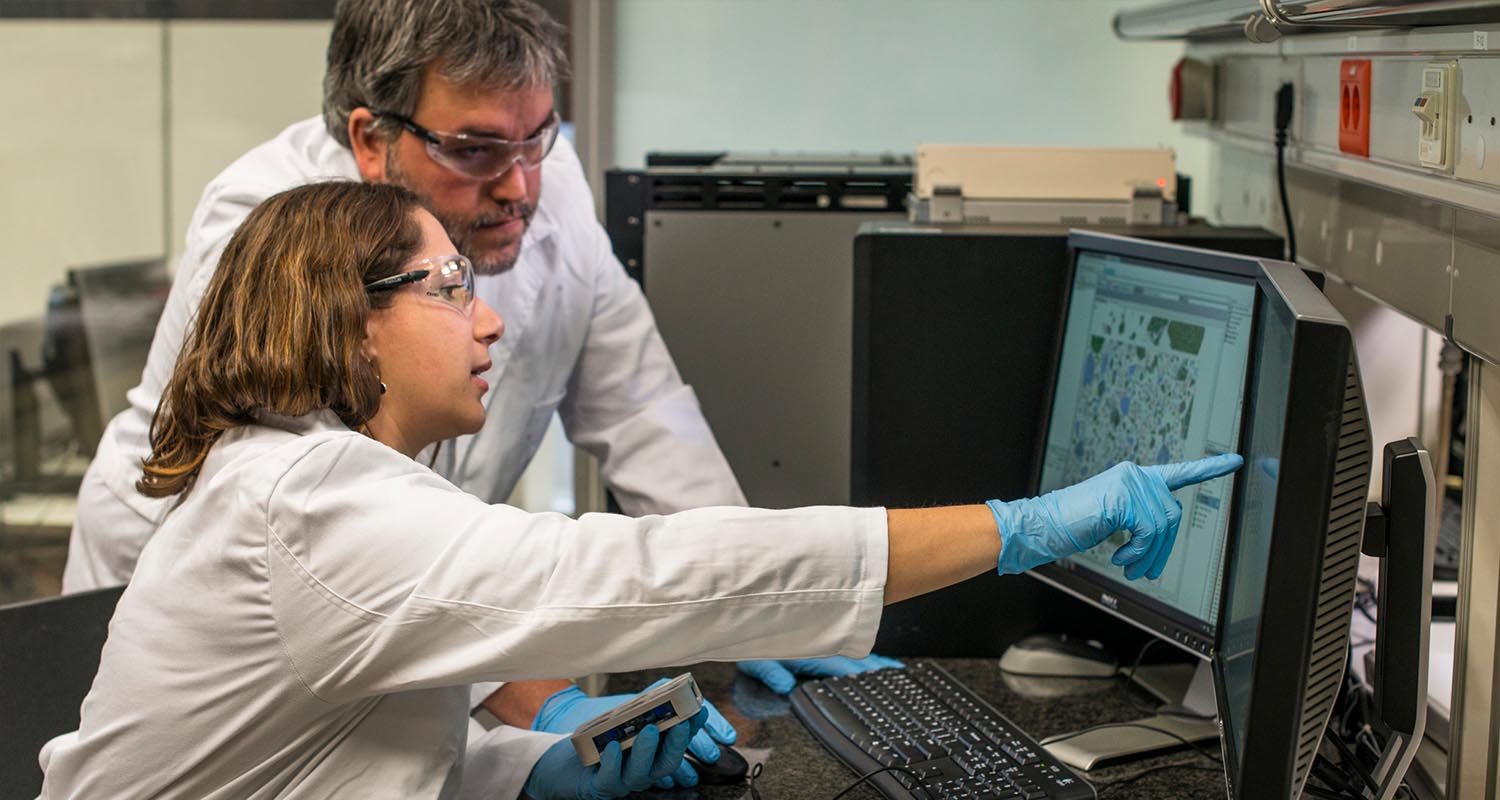

The INSILICO project, co-funded by FEDER and CDTI funds, is focused on two disruptive lines of research. First, it focuses on research for the development of bimetallic catalysts for the production of hydrogen from seawater, an abundant and untapped source, using catalysts that facilitate the electrolysis of water more efficiently and with lower energy consumption. The second line of research is focused on the production of propylene oxide, a basic component for the manufacture of a wide range of plastic and chemical products. Using bimetallic catalysts designed by a combination of machine learning and experimental trials, the project seeks to improve these processes.

This project seeks the development of new specific bituminous mixtures to withstand high transverse and tangential stresses for their implementation in wearing courses and minimize the occurrence of winding and disintegration in the road surface. The specific objectives refer to the improvement of adhesion between pavement layers, the improvement of cohesion, ductility, and tenacity of the bituminous mixture to be developed, and the reduction of CO2 emissions and carbon footprint.

OAS, operational advisor system, is a project that aims to use a strong artificial intelligence system for the control and stabilization of processes in oil and gas plants. This action shows a flexible Plant Operator solution in a real environment, based on new algorithms or mathematical models supported by strong Artificial Intelligence technology (Deep Learning and Reinforcement Learning) developed by Repsol, with the aim of optimizing the control and stabilization of industrial processes through the reduction of the duration of the transient time.

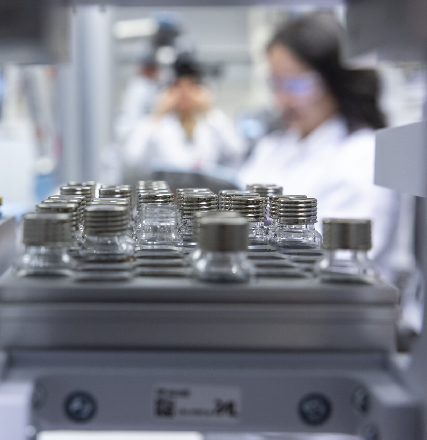

The Plastics2Olefins project seeks to develop a high-temperature pyrolysis technology to convert plastic waste into circular olefins, thus reducing the carbon footprint of the chemical products produced. Coordinated by Repsol and made up of several companies, technological centers, and universities, this project, financed by the European Union, is aligned with the circular economy principles and objectives of the European Green Deal. The technology is initially developed in a pilot plant at Repsol Technology Lab, then it will be escalated to a demonstration plant in Puertollano. This progress will significantly contribute to the EU's efforts to achieve climate neutrality by 2050 and establish a new technological route for the production of plastic raw materials with low-carbon footprint.

We lead this technological project in the Community of Madrid with the aim of encouraging public-private collaboration in the region. In this initiative, the IMDEA Energy Institute, research center on renewable energy technologies, Ariema, leading Spanish company in hydrogen and fuel cell technologies, Seenso Renoval, Spanish company that since 2004 has led the development for the thermal use of solar energy, and EvoEnzyme, spin-off from the CSIC’s biotechnological base with extensive background in biocatalysis and the first Spanish company in directed enzyme evolution, also take part.

This innovation hub focuses its efforts on the development of new technologies that allow the use of all kinds of waste as new raw materials to produce materials and renewable fuels. Because of its relevance, it has been selected by the Community of Madrid as part of the Regional Research and Innovation Smart Specialization Strategy.

The REMO Project, promoted by the Spanish State Research Agency (AEI), seeks to develop pioneering technology for detecting seismicity at sea with a precision level far superior to the tools currently available to seismologists. This technology will help to better study seismic events such as earthquakes and tsunamis.

The project is focused on the search for sustainable alternatives for the chemical recycling of polymers, with the aim of strengthening circularity in this process. This involves the use of renewable monomers and sustainable chemical strategies to improve the efficiency and eco-efficiency of the polymer life cycle. The main goal is to develop scalable chemical recycling methods that allow the production of circular polymers or high value-added products from real waste streams. Moreover, it seeks to develop predictive models that allow to assess the quality of products obtained through chemical recycling, thus contributing to a more effective and responsible management of resources.

UPGRES is a research project focused on the recovery of sub-products obtained in the production of biomethane and bioethanol. The current outlet for these sub-products is the landfill so their recovery minimizes the environmental impact. Said recovery is carried out through an innovative combination of technologies encompassed in biotechnological and thermochemical platforms, mainly.

Behind the UPGRES project there is a public-private consortium made up of a research center (IMDEA), a university (URJC), and two companies (REPSOL and INGELIA) that provides a solid foundation in the most relevant aspects of the project.

The ZEPPELIN industrial research project will seek innovative, efficient, and circular technological solutions for the production and storage of green hydrogen. Its main purpose will be to discover alternatives to electrolysis that promote the circular economy through the recovery of waste and by-products from various sectors (agri-food, textile, WWTP, refineries, and more). New materials for storing green hydrogen and modeling tools for the new technologies will also be developed.

Find out more about the European Economic Area-Grants Projects

-

NEOSPOL PROJECT: Creating new materials from refinery byproducts (Only available in Spanish)See pdf (441,49 KB)

-

ECOENERGY PROJECT: Fuels that pollute less and are more efficient for producing heat in homes (Only available in Spanish)See pdf (354,14 KB)

-

PHARO PROJECT: Photocatalytic asphalt road, asphalts to reduce levels of NOx (Only available in Spanish)See pdf (389,46 KB)

-

BIO4FUEL PROJECT: Turning waste into biofuels. (Only available in Spanish)See pdf (186,09 KB)

-

LAE PROJECT: Energy-saving, high-efficiency lubricants (Only available in Spanish)See pdf (297,84 KB)

The goal of the HPC4E project is to apply new exascale HPC techniques—which are capable of a quintillion (billion billion) operations per second—to industrial energy simulations, thereby customizing them. HPC4E aims to move a step beyond the state of the art in HPC simulations required for different sources of energy:

- Hydrocarbon exploration geophysics

- Efficient combustion systems for biomass fuels (biogas)

- Wind power production and design

The Repsol-ITMATI Joint Research Unit was created with the goal of developing mathematical and computational methods to solve complex simulation and optimization problems. It also intensifies the public-private partnership in R&D&I and introduces the latest developments in applied mathematics and operating research to the industrial world in general and the energy sector in particular.

Repsol has been granted with a financial aid for its Research and Development Project named DEVELOPMENT OF NEW ADVANCED POLYOL COMPOUNDS (POLCA). The Centre for the Development of Industrial Technology (CDTI) manages this financial aid that is co-funded by the European Regional Development Funds 2014 - 2020.

Updated as of October 2025.