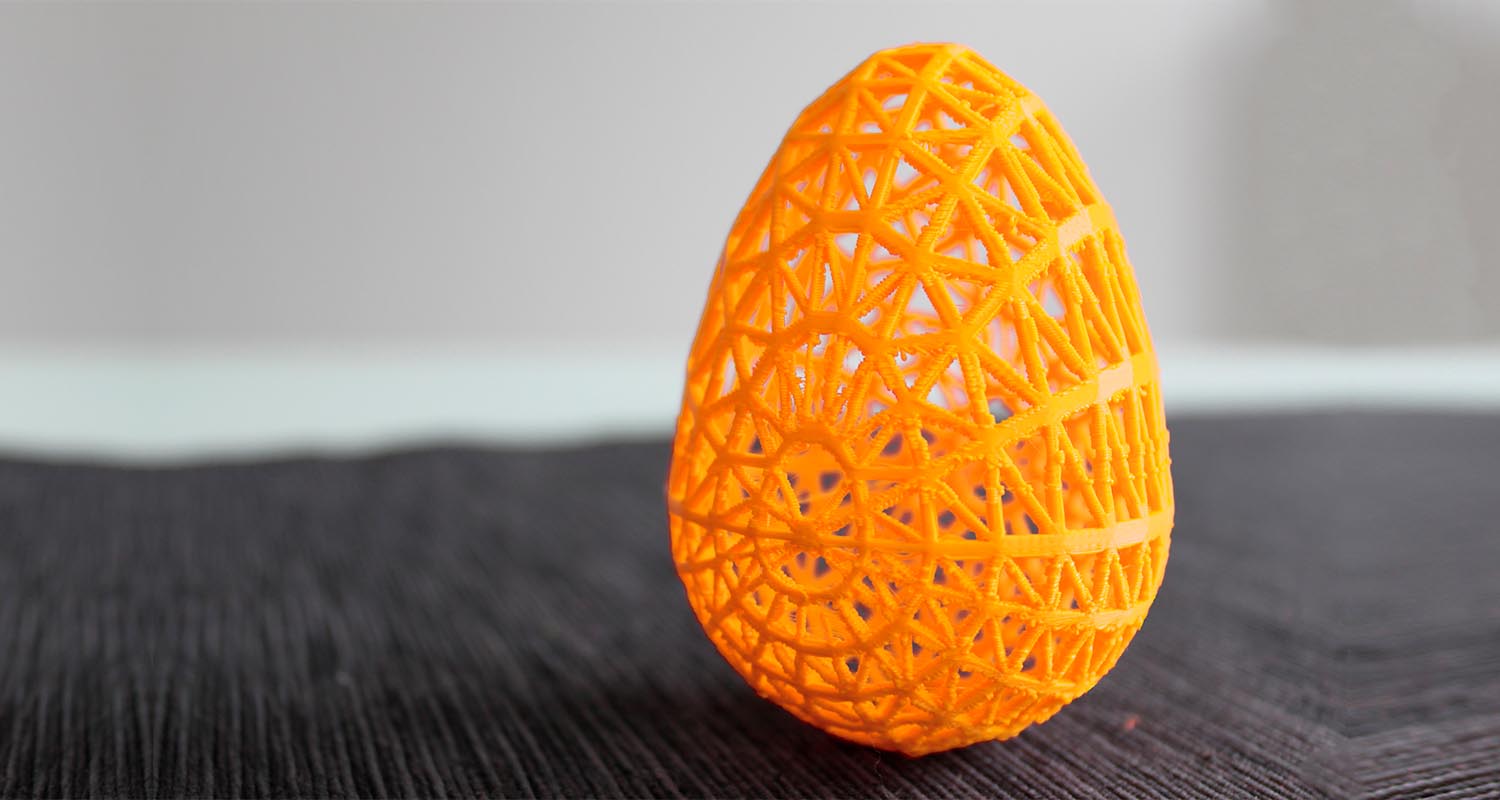

3D printing

Our PP·3D range

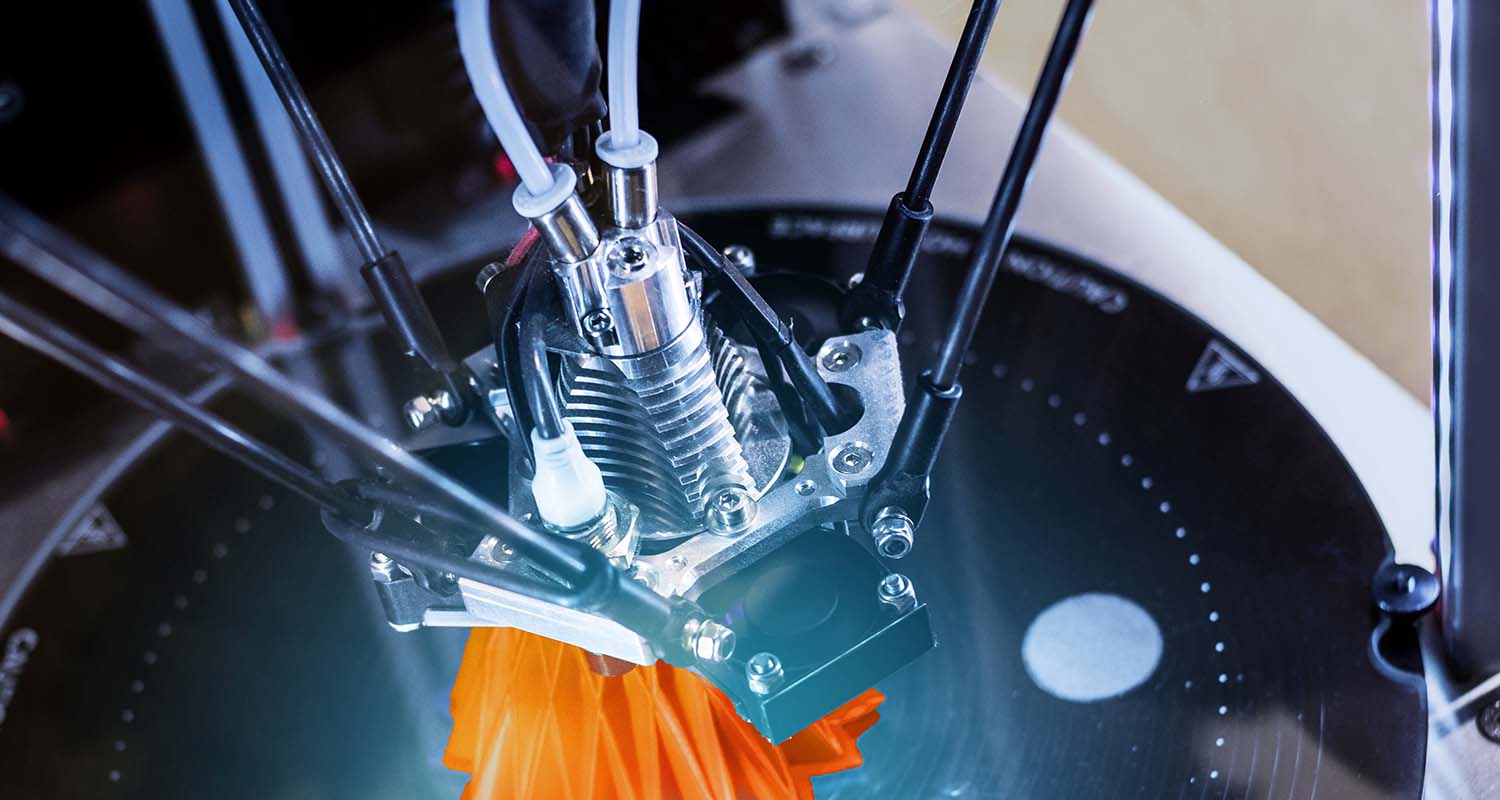

We have designed a complete polypropylene catalog for 3D additive manufacturing. The properties of these tailored polymers are modified to meet the most demanding requirements of this market segment. Our range of PP·3D is apt for the manufacture of filament for the FFF technology (fused filament fabrication), also known as FDM (fused deposition modeling), for its use directly in pellet format for equipment that uses the FGF technology (fused granular fabrication).

The excellent mechanical properties, processability, and dimensional stability of our PP·3D range allow for the manufacture of both prototypes and functional parts or tools. If we think of parts for medical equipment or spare parts for the dental industry, such as a guided surgery splint or high-volume suction devices, polypropylene provides a great advantage as it is sterilizable without losing properties. Its mechanical resistance also makes it ideal for prosthetics and orthopedic parts. Polypropylene uses for 3D printing are multiple and cover the automotive, aerospace, healthcare, furniture, and toy manufacturing sectors, among many others. Its only limitation is creativity: If you can imagine it, you can print it.