Reusing equipment and materials in exploration and production operations

Examples of projects we are undertaking:

- In 2022, the decommissioning of the Gyda rig was completed, a giant in the North Sea (Norway), delivering 18,400 tonnes of the topside and 11,500 tonnes of the jacket for recycling.

- Progress is currently being made with the Casablanca rig (Spain) decommissioning plan, incorporating circular economy criteria.

- In E&P operations in the USA, initiatives are being carried out for the reuse of valves, process equipment, control instrumentation, and solar panels from facilities that are taken out of service for use in new developments by Repsol or other nearby operators.

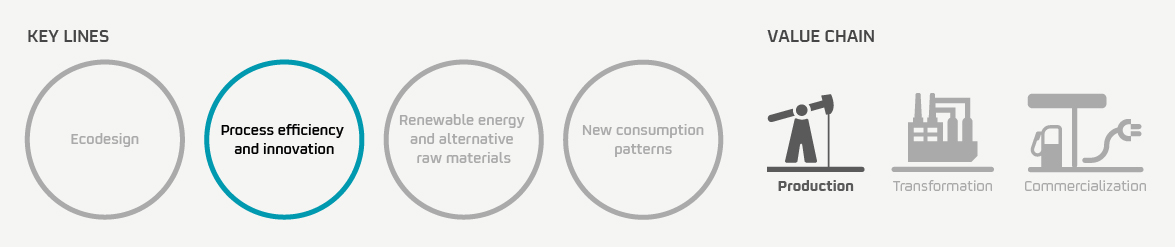

Classification by key lines and value chain

Classification by key lines and value chain

Our circular economy projects are aligned with the key lines of our strategy and are present throughout our entire value chain, from obtaining raw materials to commercializing products and services.

Find out more about our circular economy projects

Find out more about our circular economy projects

Find out more

Find out more