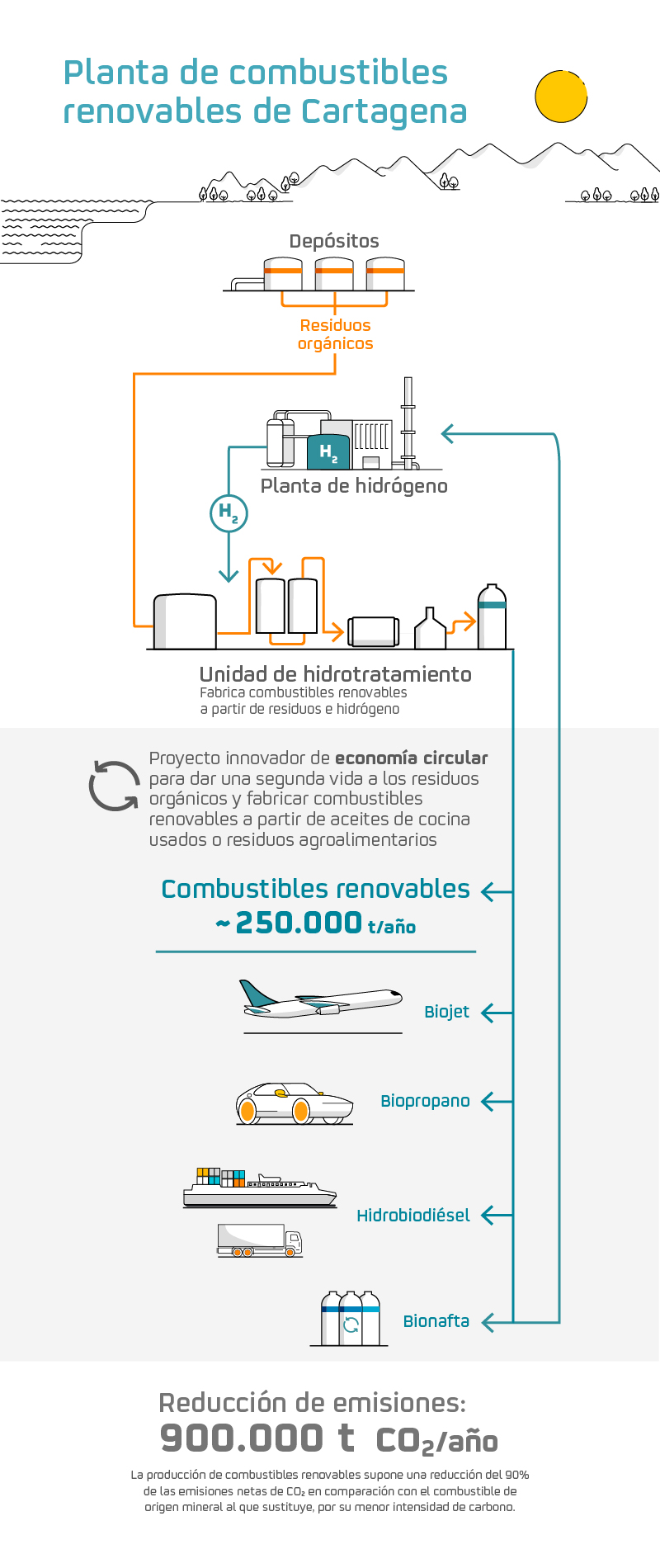

Renewable fuels from waste

At Repsol, we have been manufacturing and marketing fuels of 100% renewable origin for years. To do this, we use various raw materials, like used cooking oils and nut shells. One of their main advantages is the reduction in emissions compared to traditional fuels, since the CO2 released during their use is equal to the CO2 that has been previously removed from the atmosphere by the raw material used for their manufacture. In addition, these fuels can be used in existing combustion engine vehicles and take advantage of existing infrastructure.

Our plant in figures

Our plant in figures

€250

million euros

investment in Cartagena.

1,000

professionalsduring construction and startup.

900,000

tonnes

of CO2/year in emissions reduction, thanks to the use of recycled raw materials.

New energy solutions we are developing

Classification by key lines and value chain

Classification by key lines and value chain

Our circular economy projects are aligned with the key lines of our strategy and are present throughout our entire value chain, from obtaining raw materials to commercializing products and services.

Find out more about our circular economy projects

Find out more about our circular economy projects

Find out more

Find out more

Updated as of October 2025