Product safety

Product safety

We promote innovation for the design and manufacture of safer products

We promote innovation for the design and manufacture of safer products

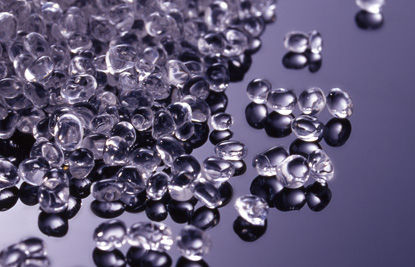

Our responsibility and commitment at Repsol is to minimize the potential risks to people and the environment in all our products, from the design stage to their launch on the market.

Product safety encompasses the responsible management of all chemical products we manufacture, purchase, use, and place on the market in terms of safety, health, and environmental protection.

To achieve this, it is essential to know the potential effects of products on health and the environment, to carry out a correct risk assessment and to communicate the safe use of chemical products properly, both in the industrial and the professional and domestic spheres.

To this end, we work closely with the competent authorities, industry associations, and external research groups, establishing guidelines in the field of product risk management, establishing best practices for the sector, and promoting research activities.

Safety Data Sheet Search Engine

Communication plays a key role in product safety

Communication plays a key role in product safety

Safety data sheets (SDS) and labels are the means established by the REACH Regulation to transmit product safety information throughout the supply chain, including to end consumers. This way, supply chain agents are familiar with the conditions for safe handling.

We have around 10,000 Safety Data Sheets

We have around 10,000 Safety Data Sheets

The CLP Regulation on Classification, Labeling, and Packaging of Substances and Mixtures is based on the United Nations Globally Harmonized System (GHS) of classification and labeling of chemicals and contains the criteria established to determine whether a substance or product should be classified as hazardous, requiring manufacturers and importers of chemical substances and mixtures to classify, label, and package their hazardous products before placing them on the market.

The CLP Regulation sets out detailed criteria for labeling elements: pictograms, signal words, and standard statements for hazard(H phrases), precautionary statements (P phrases), etc. It also indicates general packaging rules.

An emergency telephone line should also be included to assist users of the product in providing them with information on the measures to be taken in the event of safety incidents such as accidental poisoning and exposure, or to prevent their occurrence. It is available 24 hours a day, 365 days a year.

We publish and distribute Safety Data Sheets to our customers in accordance with the regulatory requirements of each country.

Product Information Sheets

We prepare and make the Product Information Sheets available to our customers for our products not classified as dangerous.

Updated as of October 2025.