We develop an innovative polypropylene compound that replaces metal in technical applications

In collaboration with Quimidroga, we have homologated a polypropylene compound that replaces metal and other heavier polymers in water treatment applications (industrial water, urban wastewater, desalination flotation systems, and drinking water). ECOTEC, a leading company in global filtration solutions, already has lamella modules made with our polypropylene compound in its product portfolio.

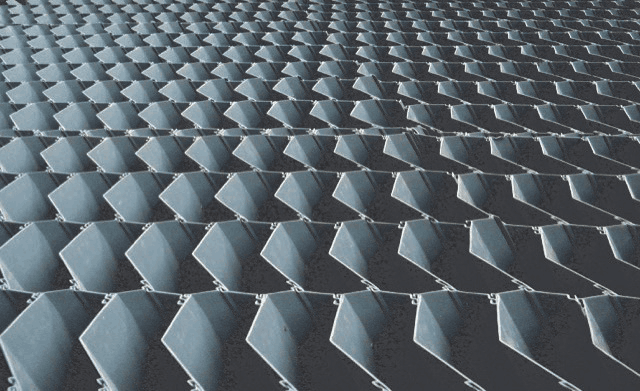

We have developed a new polypropylene compound reinforced with mineral fillers optimized for high-added-value applications as an alternative to using metals or other heavier polymers. These are large lamellar systems of up to 15 m in diameter, used by the mining industry when extracting water and leachate or at drinking water treatment facilities.

The experience in polypropylene compounds of our distributor Quimidroga enables us to be close to end customers' needs and to offer advanced solutions. Substituting metal or other higher-density polymers with polypropylene in the manufacture of the lamellar system provides numerous advantages, among which are lightweight, evading the need for on-site welding, and, due to polypropylene's innocuousness, safe for health, which allows this solution to be applied in drinking water treatment facilities that require contact with food.

Our polypropylene composite module assembly on site consequently becomes a simple process that does not require specialized personnel, offering savings in installation and allowing for single profiles delivery instead of assembled modules. Shipping single profiles can reduce the volume occupied for freight purposes by up to a tenth, which, added to the weight reduction, minimizes fuel consumption and CO2 emissions during transport.

Therefore, we offer with ECOTEC a more flexible solution to end customers that facilitates the change in geometry, adapting to the needs of each customer.

We reaffirm our commitment to offering new solutions that contribute to the competitiveness of our customers, strengthening our product portfolio by expanding the use of polyolefins in high-performance parts until now only manufactured with other types of heavier materials, as in the case of the lamellar modules. Incorporating polyolefins into parts with high technical and functional requirements represents an innovation in materials that will provide new opportunities to develop new materials for other high-performance technical parts for mining, water treatment facilities and many other industries.